| Part # |

Comments |

|

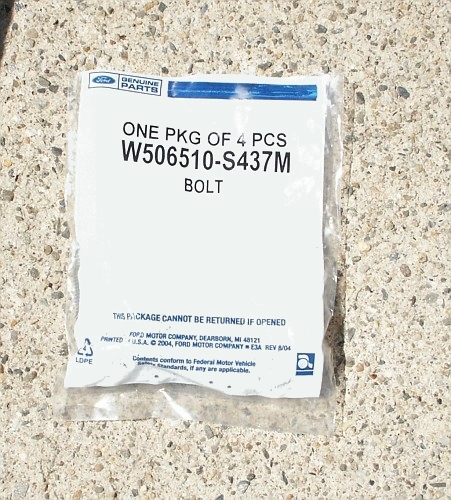

| W506510S-437M | factory installed in model year

2006 and later crown victorias 10mm bolt head bolt hardness grade 10.9 (sold in a package of 4 bolts) (see pictures below) |

$6.00 |

| N807182-S36 | M8-1.25x41 with

a flanged head 10mm bolt head bolt hardness grade 9.8 (sold in a package of 3 bolts) |

superceded by W506510S-437M |

| Part # |

Comments |

|

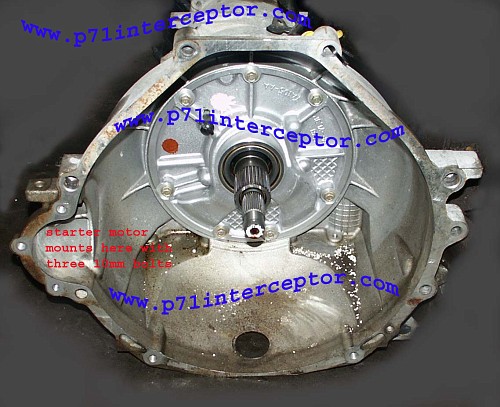

| N806184-S437 | M8-1.25x110 bolt hardness grade 9.8 |

$12.00 |

| N806184-S | M8-1.25x113.5 bolt hardness grade 9.8 |

superceded by N806184-S437 |