For today's project, we're going to be looking at how a tire and rim

seal air inside. If you've ever had a tire with a mysterious air leak

and had the shop tell you that the leak is caused by the rim bead seal,

this is what they were talking about.

Here's a tire and rim from a wrecked 2000 mercury grand marquis

This tire is junk because of a couple unrepairable gouges in the

sidewall. So some destructive cutting tools were used to pull the tire

off the rim

Here's the tire after it was cut in half.

On the surface, this may look like a nice 1999 crownvic wheel

But under different lighting, rust is visible around the rim

flange where the tire bead normally sits.

Here's the rim with half of the tire sitting next to it

And the rim with the tire cross-section installed on it

Here's a diagram of how a steel belted radial tire is constructed

Here's an actual cooper tire cut in half showing how the tire seats

against the rim flange

When the rim flange rusts like this, air can escape through the rust

pits.

Closeup pictures of the rust around the rim flange

Crevice corrosion happens in this area because water gets trapped in

between the tire and rim with no place to drain out.

Now that we've seen the rusty rim flange, lets try an experiment to

remove all the corrosion.

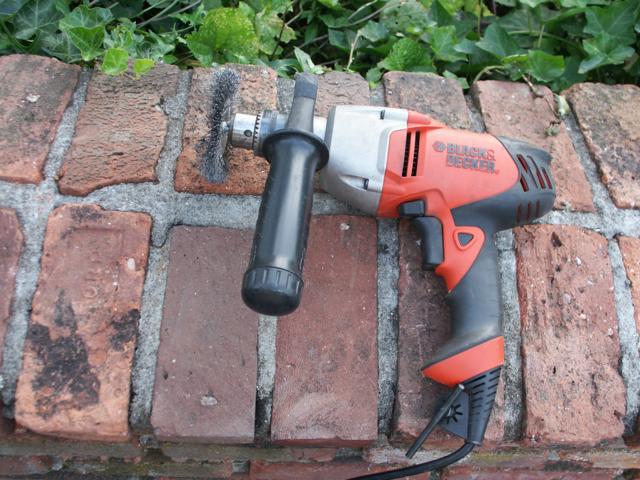

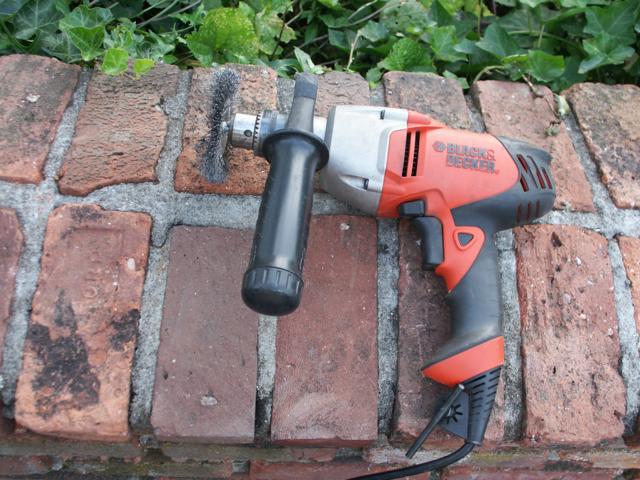

First, use an electric drill with a wire wheel to remove the loose rust

scale.

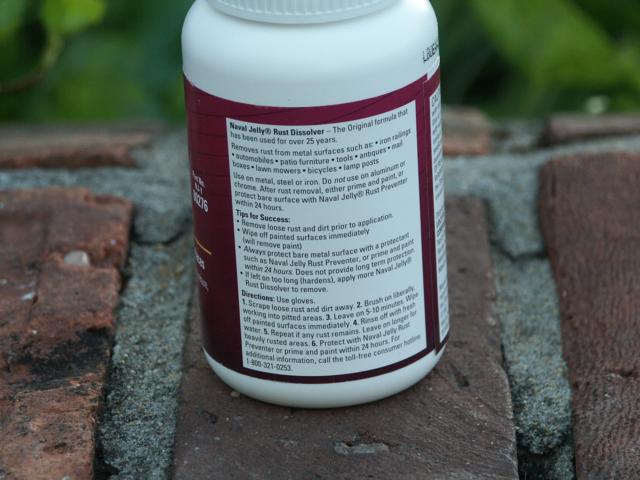

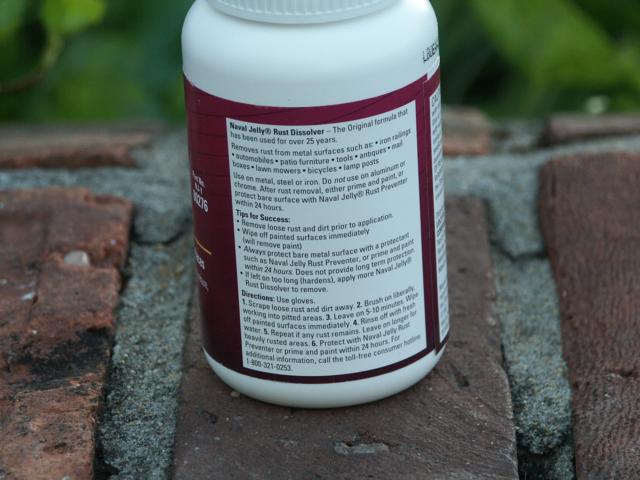

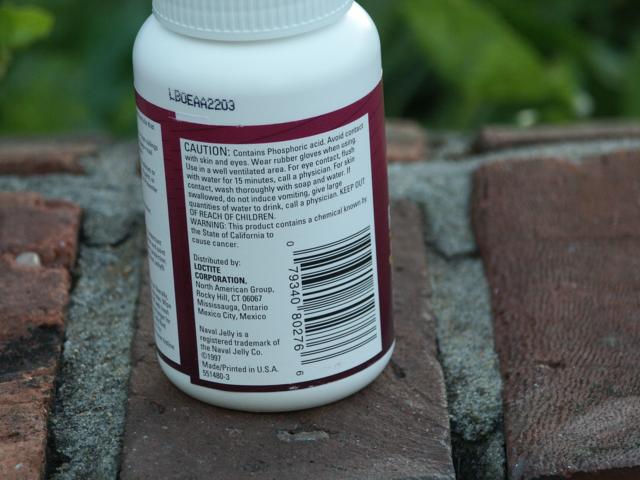

And start dissolving the rust with a phosphoric acid solution

The pink colored stuff on the rim is the naval jelly solution of

phosphoric acid. The small bubbles in the gel tell you that the acid is

doing it's job etching away the rust.

Here's the rim flange after several applications of naval jelly. The

rust is gone for the most part, but there are deep pits in the metal

where the rust pores used to be. Rust never sleeps and you want to get

rid of it all to make sure it doesn't come back.

The active ingredient in naval jelly is phosphoric acid. Unlike other

acids that eat away rust, this stuff for the most part leaves the

uncorroded metal behind untouched.

For cleaning up rust, sandblasting also works nicely. It is a lot

faster than etching rust with acid. But it does remove more "good

metal" than the naval jelly method.

The big problem now is going to be figuring out what substance to use

to fill in craters where the rust used to be. A coat of paint with

some tire bead sealant on top might work.

On rare classic cars with rim flange rust this bad, you'll sometimes

see restoration shops weld metal back to the rim flange and then turn

the rim on a lathe. But this rim is from a high volume production car

and replacement rims are plentiful at the junkyards. New replacement

steel wheels are also still avaliable for the 1998-2002 crownvics from

ford motor company too.

There was quite a bit of rust around the rim flange, but the steel is

still reasonably thick in this area. So the wheel still has a good

amount of mechanical strength left to it in the rim flange area.

Sometimes, you'll encounter rims that are so severly corroded that the

flange area has the strength of tin foil.

Getting all the rust off this rim took a few days, the process I used

was:

-Apply naval jelly to rusty metal

-Let rim sit overnight with acid solution on rusty metal

-In the morning after the naval jelly had dried, use a wire wheel on an

electric drill to remove the rust that the naval jelly had loosened up

-Then reapply the naval jelly to start the process all over again

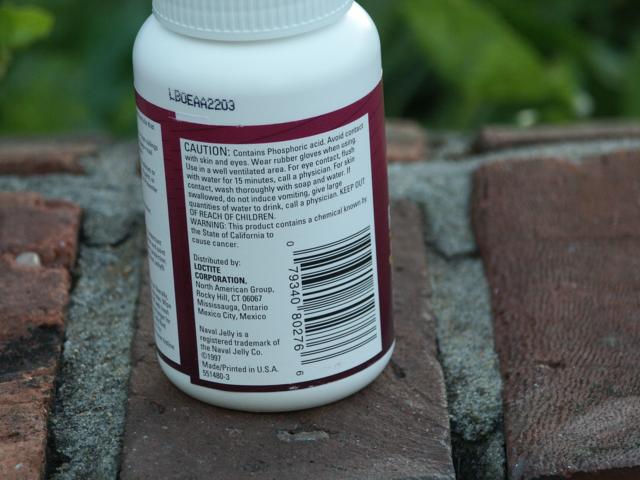

Here's the back of naval jelly bottle

Despite what naval jelly's material

safety data sheet (MSDS) may imply, the substance is relatively

safe to handle. But it would still be a good idea to use the substance

outdoors or in a well ventilated area to prevent the buildup of

irritating fumes.

Wheel Balance Weights

Here is a wheel balance weight on the rim

The clips on these do not get deep enough into the flange area to cause

any leaks

Valve Stem

Sometimes, you'll encounter leaks around the tire valve stem.

Here's a 2000 grand marquis wheel with the valve stem installed

A closeup of the rim from back showing the rear of the valve stem

The rim with the valve stem removed. Notice the new circular hole that

didn't used to be there?

Here's the rim from the back showing where the valve stem would

normally insert

There are some abrasion marks on the valve stem from where the hubcap

was rubbing against it. The hubcap weighs a lot less than a steel

wheel, so the two items don't always want to rotate at the same speed.

Tire Shop Air Leak Sealing Methods

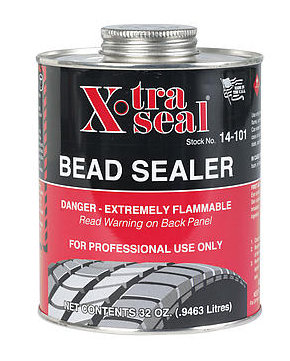

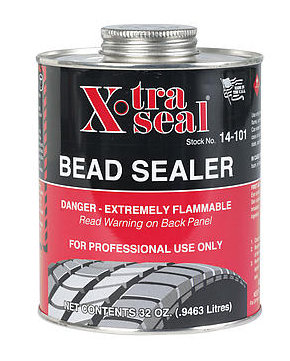

Bead Sealer

Bead sealer is a black rubbery glue substance that is used to help the

rubber tire seal to the metal rim. It

will also fill in minor imperfections in the rim. And will help keep

small debris like stones from getting in between the tire bead and the

rim flange. It does however make the tire a little more difficult to

get off the rim during service.

Air drill

An air drill with a variety of attachments are used to clean up the

tire bead and the rim flange area

Wire Wheel

On steel wheels, a wire wheel is usually used to clean up corrosion.

Scotch Brite Pads

On aluminum wheels, scotch brite pads are usually used to clean up

corrosion. Aluminum is softer than steel and scratches relatively easy.

These scotchbrite discs are also sometimes used to clean up the rubber

surface of the tire bead too.

Wire Brush

Without power tools, you could use a wirebrush on the steel wheels

instead. Rust cleanup will take a little longer with this tool.

Bead sealer + Rusty Rim

A common practice to seal up tire air leaks on steel wheels around the

bead area is to remove the loose rust scale with a wire wheel. Then

coat the polished rust with bead sealer and install the tire. This

method did get the really rusted rim pictured above to hold air

reliably for over a year. Unfortunetly, rust never sleeps and that

wheel developed air leaks again requiring the tire to be removed from

the rim to "clean up" the bead area yet again. There's no perfect

solution besides replacing a rim with a new one once the flange is

rusted this badly.

Do It Yourself Tire Leak Repairs

You'll sometimes see the do-it-yourself crowd install large quantities

of tire sealer via the valve stem in an attempt to stop bead leaks.

This stuff has a poor success rate at repairing air leaks around the

tire bead. It does however make a real mess in between the tire and

rim. And it will also throw off your wheel balance.

Other Notes:

- A common practice to pinpoint leaks is to submerge a wheel into a

large container of water. If you see any bubbles coming out of the

water, then you've got an air leak in that area.

- Another common practice to pinpoint leaks is to apply a mixture

of soap and water onto the tire. When you see lots of bubbles coming

out of an area, you've got an air leak there.

- Ford crown victorias recieved a tire pressure monitoring system

(tpms) starting in the 2008 model year. In 2007 model year and earlier

crownvics, you can ride around all day with low air pressure in your

tires without any warning lights illuminating on your dashboard

instrument cluster.

- The rim pictured above is really damaged around the bead flange

area

from corrosion. For a reliable air seal, the wheel should be replaced

with a new one.

- This webpage was compiled to give car owners background

information

about what a "tire bead leak" means. Tire shop technicians that

frequently work on older vehicles in the northeastern united states

will have lots of practice sanding down rusty rims and applying bead

sealer.

- For removing a tire from the rim, the general car owning public

is

going to be at the mercy of their local tire service shop. The

equipment to pull a tire off the rim, install a tire onto the rim, and

then rebalance the wheel costs thousands of dollars to purchase. But

when you've got a mysterious tire air leak, it's still useful to have

background information about how a tire seals onto the rim so that you

can have a more productive discussion with the technicans at your local

tire shop.

- I started a discussion thread on the hotrodders.com message forum

to solicit comments about this corroded wheel. This is an "old school"

steel wheel that's constructed much like the ones on yesteryear

hotrods. Here's

a link to the discussion thread.