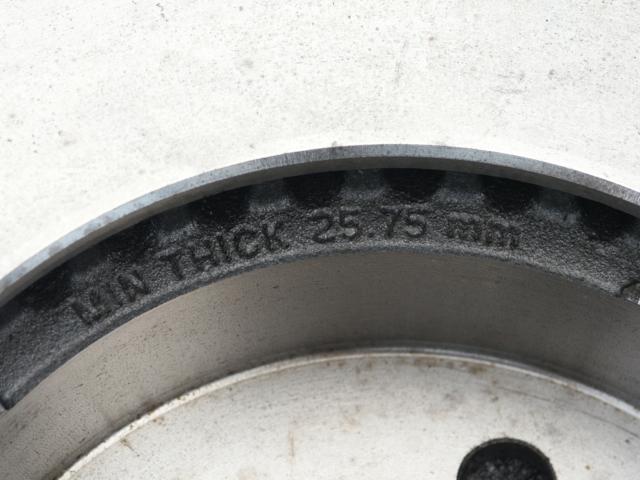

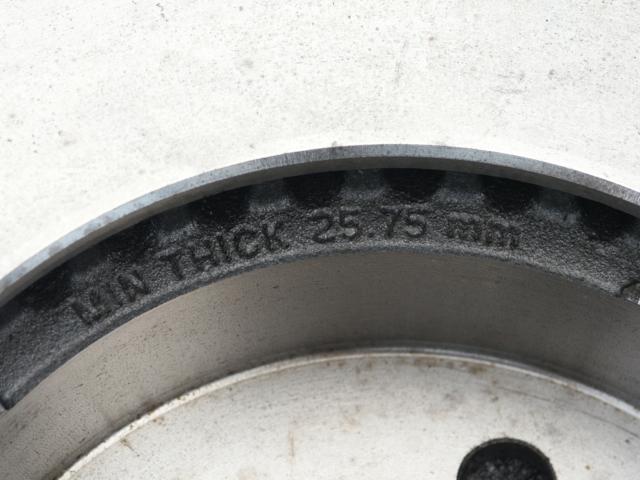

Below are pictures of two brake rotors for a 2000 ford crown victoria.

One is an original equipment ford rotor that has been installed on the

car for about 10 years ago. The other is a New Old Stock (NOS) rotor

that was produced about 10 years ago and has been stored in a humidity

controlled enviroment since manufacture.

These two rotors were made using the same castings. But do you notice

how the rotor on the right looks very different near the cooling vanes

due to all the thick rust scale?

In the northeastern united states, massive quantities of chloride salts

are applied to the roads during the winter to clear snow and ice. This

makes driving on roads around here similar to a salt water marine

enviroment.

Before the rotor was removed, the car was parked outside overnight. In

the morning, a layer of condensation was present on the car causing

flash rust of the rotor except for where the pad was.

Whenever the rotor with all the thick puffy rust would be moved around,

a layer of rust scale would fall off. Here's a little bit of it.

The F8VZ-1125-AA part number tag also has a date code on it of 08/29/00.

Thick bubbly rust like this restricts airflow through the cooling

vanes. This can cause the rotor to overheat. There have also been reports of aftermarket

"lightweight rotors" breaking in two when they get rusted this bad.

The cooling vanes are designed to move lots of air through. During the

winter months, the air on the roads will have a very high salt

concentration. This stuff builds up and leaves a salt crust layer which

never really evaporates either. So even during the non-salty summer

months, the rotor is still covered in salt from the wintertime.

This is an oem ford rotor for the 1998-2002 crownvics

It was made in brazil by Varga

which is currently a division of TRW.

A rear rotor for a 2000 crownvic next to the front rotor. The majority

of the stopping power comes from the front brakes not the rear

Here are some pictures of the rear brake pads from the car. Besides

being really worn down, another problem with these pads was that there

was thick scaly rust forming in between the backing plate and the

friction material

No matter how good you glue the friction material to the metal, it

doesn't do any good if the metal you glued to rusts away

In the industry, there is also a term called "rust-jacking". This

refers to how rust can be incredibly strong and lift away another item

with great force.

Having a nut become rust-jacked onto a nut is really common around

here. But sometimes cars around here get oddball rust-jacking problems

too like having a mounting bracket on a caliper flex hose puff out so

much that it crimps off brake fluid flow through the hose.

Most mechanics in the northeastern united states will have seen rotors

and brake pads like this more times than they can count. But rust this

bad will probably seem foreign to many mechanics in an area of the

country where chloride salts are not used on the roads during the

winter months to clear snow and ice.