1992 and later crown victorias have a Drum-In-Hat (DIH) emergency brake

setup. Conventional hydraulic braking is accomplished by the brake

caliper clamping the brake rotor between two brake pads. To the

surpise of many crownvic owners, the emergency brake setup is actuated

by expanding a set of minature brake shoes against the inside of the

brake rotor hat.

Here is the driver's side rear of a 1997 crown victoria police

interceptor with the rear wheel and brake rotor removed. The brake

caliper has been loosely reinstalled on it's floating mechanism.

These shoes show some wear. But there's no evidence of the brake lining

material breaking into little tiny peices from being rust-jacked off

the metal like some new england crownvic owners have expierenced.

Here is the passenger's side rear of the car with the wheel and brake

rotor removed. The brake caliper has been loosely reinstalled on it's

slides.

If you're observant, you'll notice that the brake caliper on the

passenger's side of the car is located towards the front of the axle.

But on the driver's side, the caliper is located to the rear of the

axle. This is because the same e-brake backing plate mechanism is used

on the driver's side as on the passenger's side. Just rotate the

backing plate over 180 degrees, and you can swap the mechanism side to

side.

The rear axle seal has a small leak on this side. But it's not leaking

significantly enough at this point in time to cause problems with our

e-brake system.

And with the caliper removed

A while back, a mechanic had replaced the portion of metal brake tubing

that runs from the front of the driver's door to the rear wheel well

because it had rotted through and was leaking fluid. This

spliced-in-tubing worked good for a while. But it was a little too long

and not routed quite like the oem ford installed tubing, so it rubbed

against things as the car was driven. When these pictures were taken,

the splice junction in the rear had just sprung a large leak causing

the hydraulic brakes to become inoperative. The e-brake was in need of

adjustment and wasn't holding very good at the time. Luckily, the

parking brake inside the transmission could still hold the car

stationary.

Here's the old "warped" brake rotors that vibrated badly when the

brakes were applied.

These sat outside overnight during a humid summer night and have a

little surface rust on them.

Here's a new set of brake pads and a new rotor from autozone. Notice

how the inside of the rotor hat is finely machined to accept the

minature set of e-brake shoes?

Now the new rotors can be installed

Many mechanics have been known to pound a stubborn rotor off with a

large hammer. But using a 3-jaw puller to press the rotor off will

eliminate the chance of damaging the axle shaft & carrier bearings

causing expensive repairs in the future.

To figure out whether your car has phenolic or steel pistons inside the

rear brake calipers, you need to flip a coin:

Heads=Phenolic Pistons

Tails=Steel Pistons

Since the coin

flip is inaccurate about 50% of the time, many crownvic owners just

purchase both styles of brake pads for their crownvic and return the

pad set that they don't need. Some retail autoparts stores frown upon

this method of purchasing brake pads, but the local autozone was

friendly and didn't mind.

Notice how one pad has the large rosebud clips and the other the small

clip?

This poor car has a multitude of problems. Not only have hydraulic

& mechanical brake systems failed, but the front passenger side

aftermarket napa swaybar link seperated at the ballstud too. This

caused the swaybar to bang up against the control arm. Also, the brake

hose has lost significant amounts of material from rubbing against the

remnants of the broken swaybar link and appears likely to burst open in

the near future.

The big problem with this aftermarket lubed-for-life swaybar link is

that the boot doesn't seal out moisture. This allows water to get in

and corrode things resulting in joint failure.

Be warned that napa is still selling this poorly engineered stabilizer

link for use on people's cars. I was tempted at the time of failure to

open a complaint with the NHTSA

about this part. Not only will the car sway a lot side-to-side without

a working sway bar link. But the hydraulic brakes will fail too from

flex hose abrasion if the car is driven enough. This part was not very

old when it failed and did not have very many miles on it either.

Here you can see the back of the stabilizer link ballstud still

attached to the back of the steering knuckle

Being a new england car with lots of exposure to chloride salts, the

bleeder screws on both front brake calipers are seized in place. So two

remanufactured brake calipers are going to have to be installed before

the new brake flex hose and metal tubing can have the air properly bled

out of them.

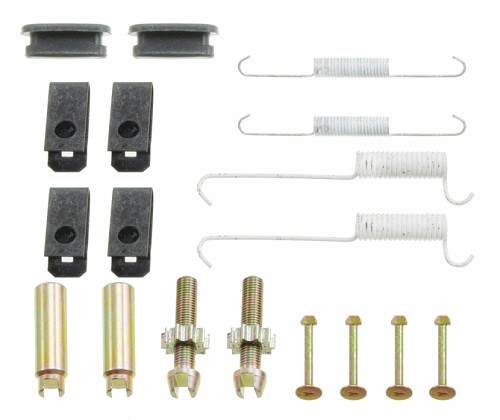

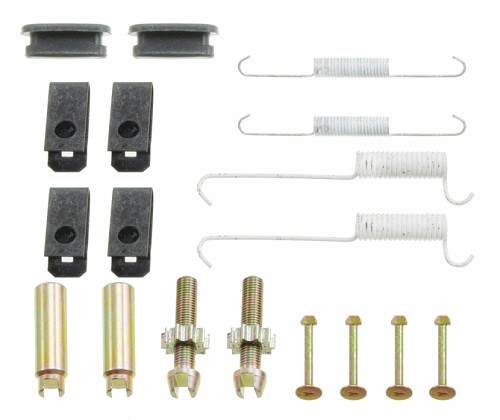

Replacement emergency brake shoes & hardware kits for 1996-2002

crownvics are avaliable aftermarket. Aftermarket offerings include:

Autozone H7415 Hardware Kit

(Also sold as: Dorman HW7002 Hardware Kit)

Raybestos H7002 Hardware Kit

Raybestos 745PG Parking Brake Shoes

Autozone 745 Parking Brake Shoes

And here are some pictures of an F7AZ-2C220-AB backing plate adapter

for 1997-1998 crownvics

Somewhere along the line, the spring near the adjuster wheel appears to

have gone missing

This backing plate is in really nice condition having never been

installed on a car. Usually, you'll find the backing plate has

significant rust on 10+ year old vehicles. Some people have evern

reported that the backing plate on their car rusted completly through

near the points where it mounts, though this does not appear to be a

very common occurence.

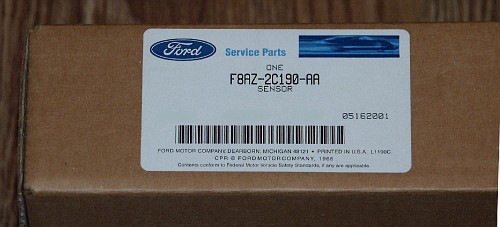

Here is the backing plate with a F8AZ-2C190-AA antilock brake sensor

installed

To remove the axles from the car, you need to push the antilock brake

sensor out of the backing plate adapter. This is really easy to do when

all the parts are new. But on an older "salt belt" vehicle, you'll

often damage the sensor beyond repair when it is forced out. The

ferritic backing plate expands inwards as it corrodes, effectively

rustjacking the sensor in the backing plate adapter.

Here's a closeup of how the emergency brake cable connects

Here's the end of the e-brake cable that connects to the backing plate

Here's the self adjuster that hangs under the car near the rear drivers

door

The ebrake cable comes in a few different sections that need to be

spliced together. Here is a closeup of where the cables would normally

crimp together.

This is the rubber insulator that suspends the cable away from the

floor pan.

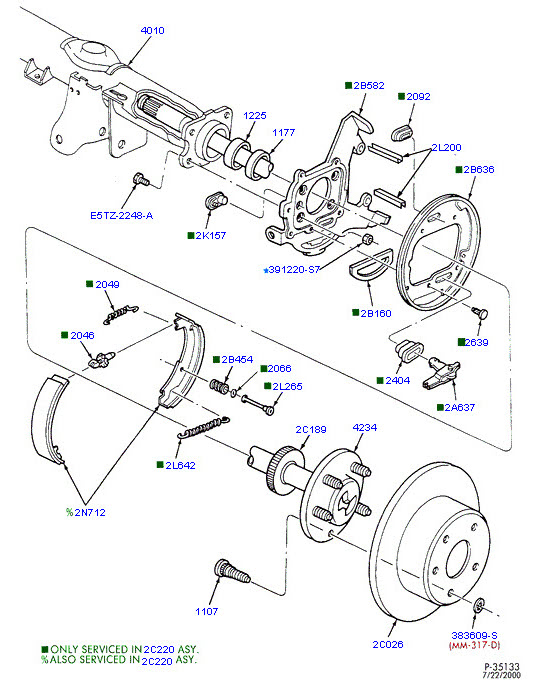

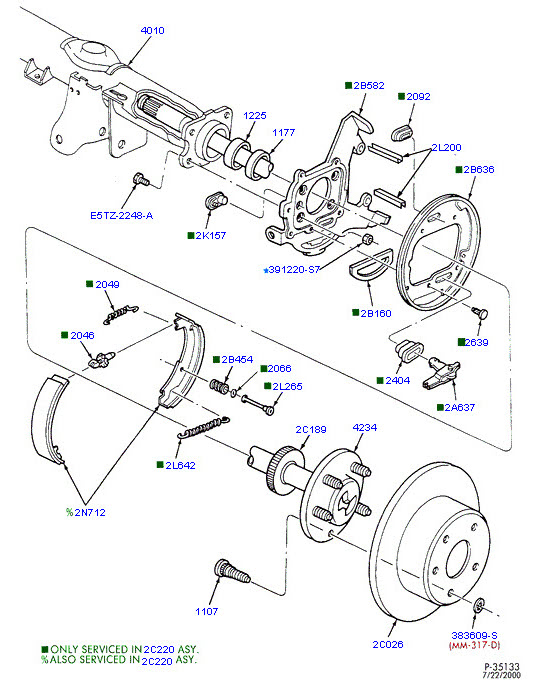

Ford service part e-brake diagram

Adapter backing plate assembly part #'s:

F1VY-2C220-A (1991-1995) (Discontinued - Obsolete)

F2AZ-2C220-A (1992-1992) (Discontinued - Obsolete)

YW1Z-2C220-AA (1996-2000) (Replaces F6AZ-2C220-A & F7AZ-2C220-AA

& F7AZ-2C220-AB )

1W1Z-2C220-AA (2001-2002)

Parking Brake Shoe Linings

F1VY-2N712-A (1992-1995)

7U2Z-2V753-A (Replaces F6AZ-2N712-A & F6AZ-2N712-B &

YW7Z-2N712-AA) (1996-2002)

Axle service part #'s:

F2AZ-4234-B with ABS (28-spline) (replaces F1VY-4234-B) (1992-1997)

F2AZ-4234-C without ABS (28-spline) (replaces F1AZ-4234-A &

F2AZ-4234-A) (1992-1997)

F3VY-4234-A lincoln towncar limousine (31-spline) (replaces

FOVY-4234-A) (1991-1997)

F8AZ-4234-CA without ABS (28-spline) (1998-2002)

F8AZ-4234-DA with ABS with stamped steel abs tone ring (28-spline)

(1998-2002)

F8VZ-4234-AA lincoln towncar limousine (31-spline) (1998-2002)

1W1Z-4234-DA with ABS with pot metal abs exciter ring (28-spline)

(2001-2002)