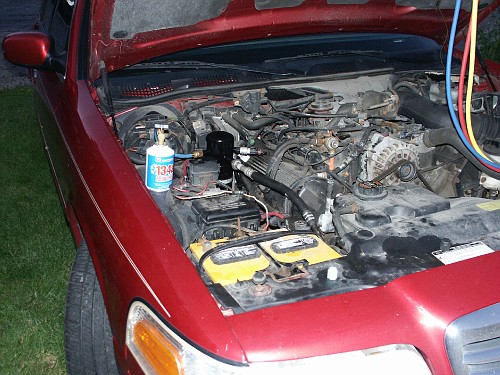

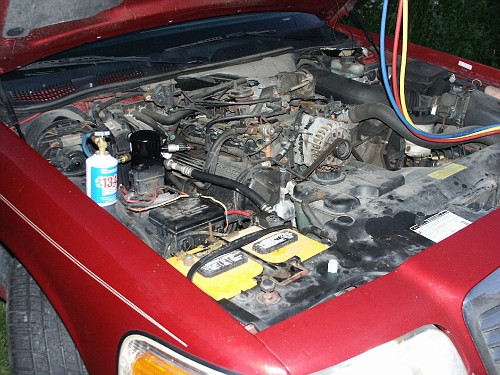

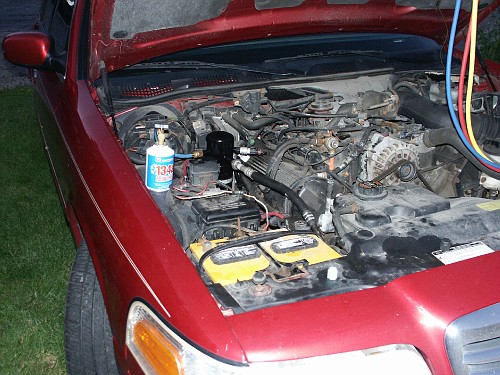

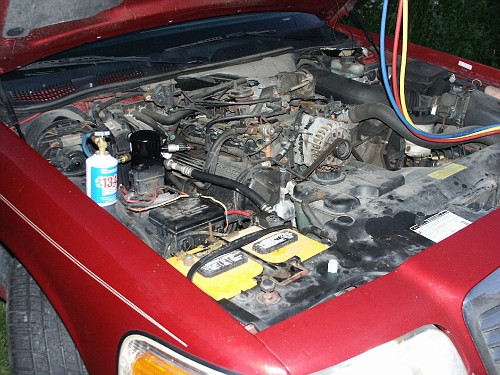

Below are some pictures of adding refrigerant to a 2000 crown victoria.

This car recently had some air conditioning system service work done

and it is completely empty of refrigerant. Factory specifications call

for 38oz of r134a refrigerant, but 3 12oz cans of r134a should be

sufficent to get the system working again.

Here's an empty refrigerant can with charging hose attached for

illustration purposes

Notice the hole pierced in the top of the can from the can tap.

The charge port on the 1992-2002 crownvics is on the low side suction

accumulator.

Although not shown, I usually boil a plastic container of water in the

microwave and partially submerge the can of r134a refrigerant in the

water during the recharge procedure. This helps get all the refrigerant

out of the can during the recharge. It's obvious that there is heat

transfer going on because the hot water will become cold to the touch

when the refrigerant can becomes empty.

Be warned that the can of refrigerant will become very cold as the

car's a/c system is being recharged. So you will want to wear a thick

set of insulated winter gloves to prevent your skin from getting

frostbite.

The a/c system is currently under 29mm of vacuum, so the a/c cycle

switch is going to have to be jumpered to get the compressor clutch to

enagage.

You might want to use something other than an exposed bent paperclip to

jumper the a/c cycle switch in case it accidentally contacts the metal

chassis of the car

Now that the 3 cans of refrigerant have been added, a manifold guage

set is connected to the system.

The accumulator is sweating nicely from condensing water in the ambient

air

The metal end of the suction hose near the compressor is also sweating

from condensing water from the ambient air.

When service guage connector was removed from the accumulator, some

refrigerant and oil escaped. Ford uses factory green tracer dye in

their a/c systems that you can see below. Looks almost like antifreeze

at a quick glance.

The r134a refrigerant fill procedure was successful and the air

conditioning system in the car now blows cold. However, the highside

head pressure was 310 psi on a 75 degree day. But this

reading fell to 250psi on a 80 degree day after cleaning debris

from the condensor and evaporator with water from a garden hose. The

discharge readings are still a little high, but not so high that the

refrigerant lubricants will break down in the relatively mild ambient

temperatures of a northeastern united states summer.

After the refill, there was ice sometimes forming on the outside of the

evaporator and accumulator. This shows that compressor is creating a

good pressure differential between the suction and discharge ports, but

unfortunately minimal air flows through an evaporator that has turned

into a solid chunk of ice. So a new aftermarket four seasons low

pressure cutoff switch was installed, and the ice has disappeared for

the most part. The new switch cuts the compressor out at a slightly

higher pressure on the low end, and leaves the compressor disengaged

until the pressure builds to a slightly higher pressure than the old

switch did.

The a/c system now seemed to be working good when taking short trips

around town with mild ambient temperatures. When a longer trip was

taken on the highway during 90 degree weather, the a/c system started

to blow warm air though. Further investigation revealed cracks in the

rubber insulators on the front compressor clutch plate and some

discoloration of the compressor clutch metal from high heat. These

symptoms pointed to a clutch that was slipping during high load

conditions. So a shim washer was removed from the clutch and the clutch

seemed to be holding good during high load conditions. Some surface

wear of the clutch plates is normal on older cars. However, if so much

heat is generated during clutch slippage that the grease boils out of

the clutch bearing, then a new compressor will need to be installed.

Finally, the a/c system seems to work acceptably. The car could use a

new compressor due to clutch wear and a slight shaft seal leak. The

condensor is somewhat corroded from being blasted with chloride road

salts and sand during the winter months causing reduced heat transfer

capabilities. The two hoses that connect to the condensor have visible

corrosion around the connection points to the condensor, though the

connection points don't seem to leak noticeable amounts of refigerant

at the moment. The electric condensor/radiator fan seems to be spinning

a little slower than the 1998 crownvic that has a new fan motor

installed. However, the a/c blows cold and the car can likely be driven

for a while without replacing any additional parts in the near future.

This is not a new car that just rolled off the dealership's showroom

floor yesterday, but rather a ~10 year old car that has been driven

over 100k miles. Also, the car lives in the northeast where ambient

temperatures during the summer are relatively mild compared to much of

the country.