Removing a Stuck Pitman Arm

When replacing a pitman arm, the nut and lock washer that retain the

arm to the steering gear usually come off easily with the properly

sized socket. If a proper socket is not avaliable, an axle nut socket

intended for servicing front wheel drive cv axle assemblies will often

work in a pinch (30mm, 32mm, 34mm, 36mm, etc.).

The nut that retains the rotating stud on the pitman arm to the center

drag link usually comes off without too much effort too. From the

factory, the later crown vics use a nylon based system to lock the nut

in place. But many aftermarket replacements use a castellated nut with

a cotter pin instead.

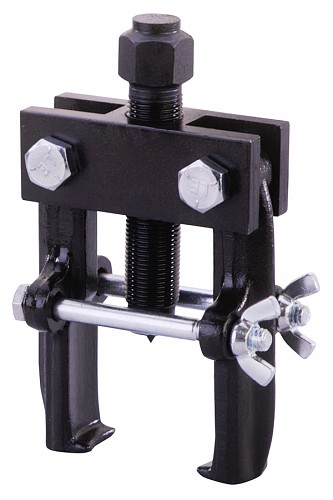

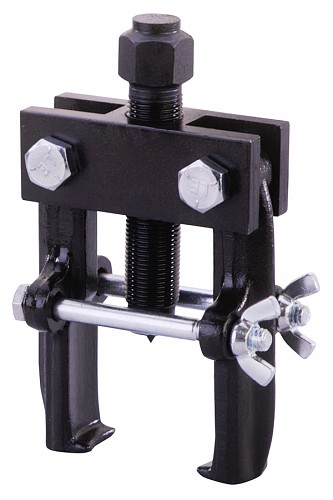

However, actually sliding the pitman arm off of the steering gear

output shaft is sometimes rather challenging. According to the ford

service manuals, simply place the appropriate pitman arm puller on the

pitman arm, tighten the pressing bolt, and the arm will pop right off.

However, this is often not that case with a pitman arm that has been in

place for several years.

In this particular case, the pitman arm was seized onto the gearbox and

tightening down the forcing bolt only resulted in broken pitman arm

pullers. The ford service manual does not have a procedure for this

particular complication. But in the field, there are a few possible

solutions:

-Heat the arm with an acetylene torch, and then use the puller. But

this is likely to damage the hydraulic seals inside the box along with

the output shaft bearings.

-Bang a large balljoint "pickle fork" seperator in between the gear and

the pitman arm with a big sledge hammer. Also likely to damage the

output shaft bearings inside the box.

-Use an angle grinder to cut a notch in the pitman arm around where the

sector shaft passes through the pitman arm.

For this project, the method of cutting a notch in the pitman arm is

going to be used as it's the least likely to damage the gear box.

So here's the box with the stuck pitman arm.

Here's the gearbox with the notch cut into it near the sector shaft.

In this case, the grinder cut a deep notch into the arm without cutting

into the sector shaft at all.

The arm now popped right with a pitman arm puller after a pressure

relief slot was cut into the metal.

Here's the gearbox that previously had a pitman arm that wouldn't come

off

And here's the tool that was used for the job. A 4.5" electric angle

grinder with a thick abrasive metal cutoff wheel.

The electric angle grinder makes easy work of pitman arm. But it also

makes lots of sparks and dust in the process. So make sure to wear eye

protection

and a dust mask too.

There was some localized heating to the arm using the angle grinder.

But this heat was minimal compared to the flame of a 4000+ degree

oxygen/acetylene torch.

Some people have commented that there are stronger pitman arm pullers

that are less likely to fail when removing a pitman arm

than the cheapie autozone $10 one pictured above. While this is true,

there are also some pitman arms stuck on the sector shaft so good that

you can break even the best pitman arm pullers.