A 1998 crown victoria with an aftermarket perfect circle idler arm

installed.

A 2000 crown victoria with a badly worn stock original equipment ford

idler arm installed.

A 1997 crown victoria with an aftermarket perfect circle idler arm

isntalled

A 1998 crown victoria with a wornout aftermarket napa idler arm

installed

A 1998 crown victoria with the idler arm removed

The idler arm & pitman arm removed and the center link hanging by

the tierods.

Here's the stubborn idler arm from a 1997 crown victoria being pressed

off the center link with a pitman arm puller

After the idler arm was removed from the centerlink, the sleeve was

still stuck on the centerlink stud

So the remainder of the idler arm stud was removed using a hammer and

chisel

The remainder of the stubborn idler arm sleeve is finally removed from

the center link

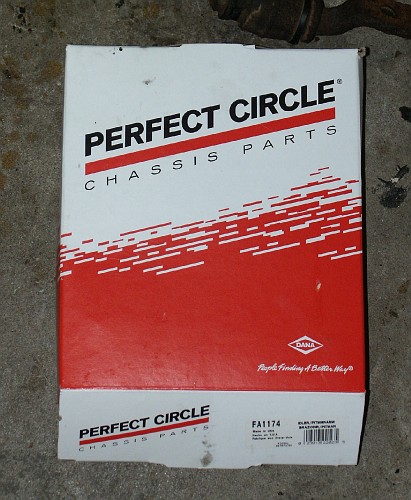

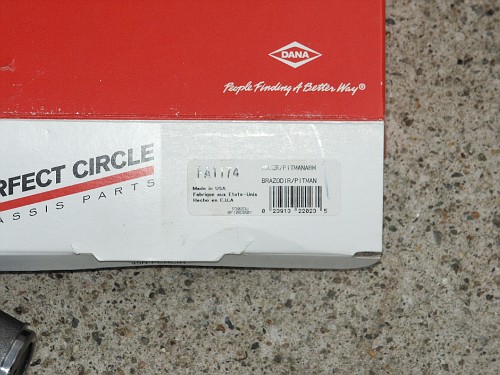

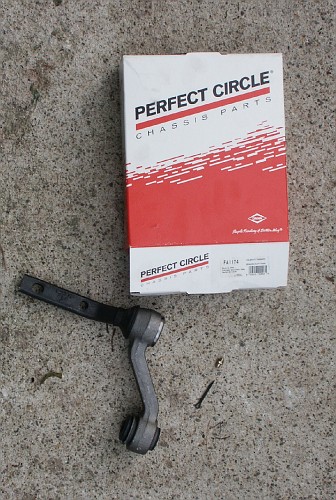

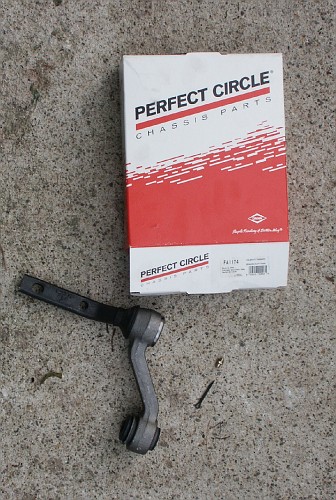

A new aftermarket perfect circle idler arm can be installed

This idler arm utilizes a metal bearing at the frame junction point

rather than a rubber bushing like the original equipment part.

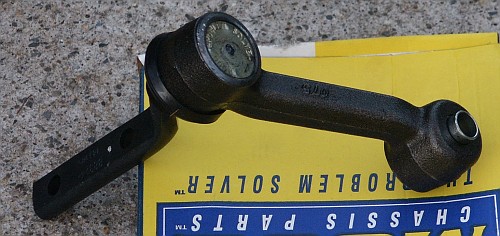

The perfect circle replacement idler arm next to the stock original

equipment idler arm

The new idler arm installed onto a 1997 crown victoria police cruiser

Most of crown victoria idler arms are retained to the centerlink

utilizing a

catellated nut and cotterpin like the tierod fastening system pictured

here.

If the transmission fluid cooler lines in your crown victoria are badly

worn, they may drag against the surface of the idler arm. This could

cause poor returnability to center, or cause leaks in the lines from

abrasion.

Here is the side of the passenger's front frame rail that an extension

bar and ratchet can be placed into to hold the idler arm studs

stationary

And the front passenger's frame rail from a different angle

You can spray penetrant oil on the idler arm fasteners from the top of

the engine bay

For lubricating the aftermarket idler arm, mobil1 synthetic grease was

used.

Here is the idler arm stud and nut from a 1997 crown victoria. This

stud is supposed to remain stationary in relation to the frame rail,

but things were rather corroded and the knurls on the idler arm bolt

stripped off.

A closeup of the idler arm knurl area. When the knurls strip off, one

can use a socket and breaker bar to hold the bolt stationary

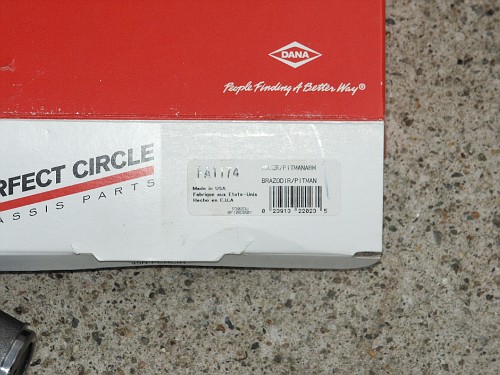

Here's one of the catellated fasteners which retains the center link to

the idler arm, and one of the nuts which holds the idler arm to the

vehicles frame.

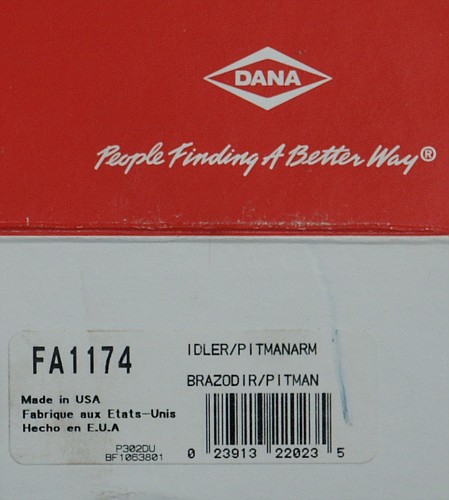

Here's an aftermarket dana perfect circle idler arm with the rubber

bushing at the centerlink side

Here's the cotterpin which retains the idler arm to the centerlink and

also the grease fitting for the idler arm bearing

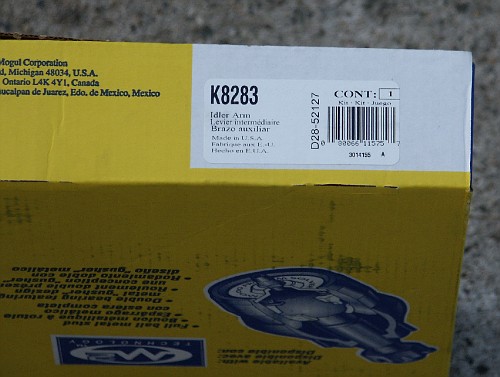

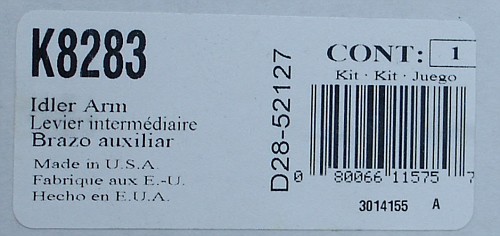

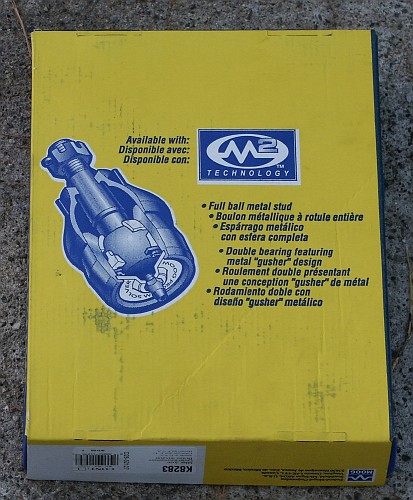

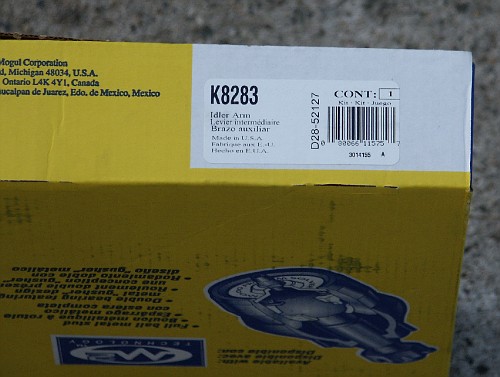

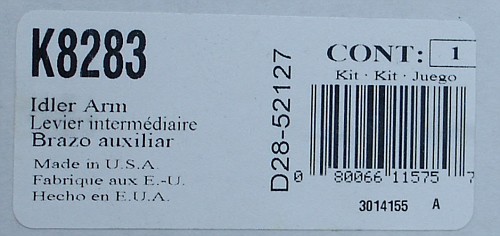

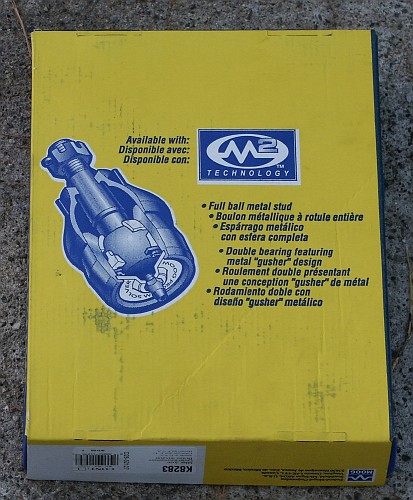

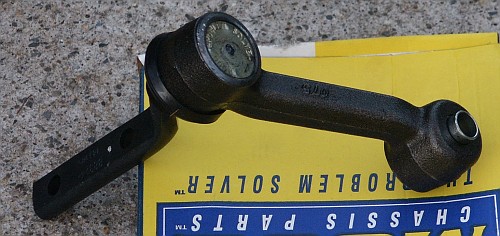

Here's an aftermarket MOOG idler arm for a crown victoria

This unit utilizes a solid metal bearing at the centerlink junction

rather than the rubber bushing pictured above. The metal bushing

improve toe control to some extent, but also increase the load on the

vehicle's frame in the idler arm area.

If this unit is installed at a commercial repair shop, a significant

advantage to this design is that the centerlink junction can be

installed at any orientation. With the rubber bushing, the rubber must

be installed at a neutral untwisted position in order to have a good

service life.

There has been some talk about durability of idler arms.

The stock original equipment ford idler arm with rubber bushings at

both junction points appears to have the longest service life out of

any idler arm.

The idler arms with metal greaseable joints have a reasonably long life

as long as you grease them regulary. But if you don't grease them

periodically, the service life will likely be rather short.

Also, much of the ordinary car owning general public think that their

oil change shop will grease their suspension components during the oil

change. But most oil change shops today actually do not grease

suspension joints as part of their oil/lube/filter specials. And if

they do, they may use a dirty grease gun with significant debris inside

which will shorten the life of the suspension joints. Some shops have

also been known to use pneumatic air grease guns which explode the

protective boot around the metal joint with excessive pressure.