Part Number

|

Callout

|

From

|

To

|

Description

|

Suggested Retail

|

1W7Z-2C335-AA

|

2C335

|

2001

|

2003

|

Traction Control On/Off Switch

|

$23.62

|

1W7Z-9G604-AA

|

9G604

|

2001

|

2003

|

Adjustable Pedal Control Switch

|

$12.32

|

XF1Z-9F924-AA

|

9F924

|

1998

|

2000

|

Speed Control Deac Switch

|

$5.29

|

1F1Z-9F924-AA

|

9F924

|

2001

|

2003

|

Speed Control Deac Switch

|

$23.91

|

F0AZ-13480-A

|

13480

|

1990

|

2000

|

Stoplight Switch Assembly

|

$14.73

|

YF1Z-13480-AA

|

13480

|

2001

|

2003

|

Stoplight Switch Assembly

|

$17.47

|

F0AZ-2B450-A

|

2B450

|

1990

|

2003

|

Brake Pedal Support Spacer (Plastic spacer in

between the brake pedal assembly housing and the firewall. Power brake

booster studs pass through this part.)

|

$6.57

|

C5DZ-2B129-B

|

2B129

|

1980

|

2003

|

Brake Master Cylinder Pushrod Spacer (Plastic

washer that goes over the rod on the brake pedal that the power brake

booster connects to)

|

$0.50

|

F1VY-9725-A

|

9725

|

1992

|

2000

|

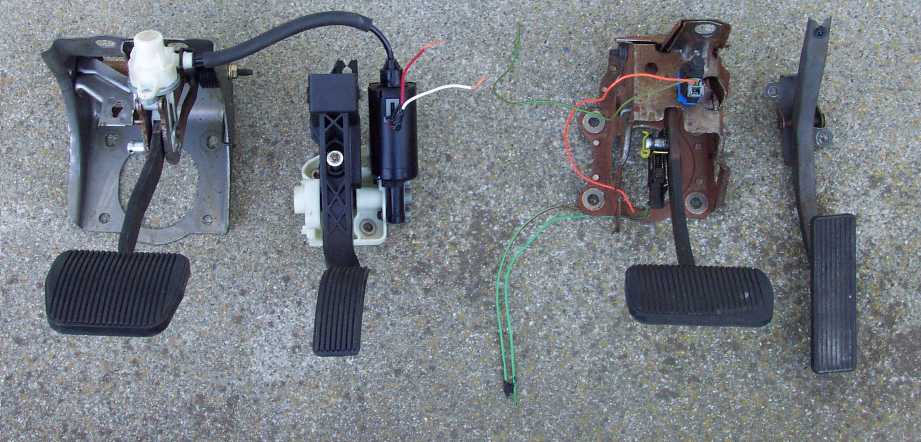

Accelerator Pedal Fixed

|

$66.06

|

1W1Z-9725-AA

|

9725

|

2000

|

2002

|

Accelerator Pedal Adjustable without Memory

|

$99.11

|

3W7Z-9725-BA

|

9725

|

2002

|

|

Accelerator Pedal Adjustable with Memory

|

$169.57

|

3W7Z-9725-AA

|

9725

|

2003

|

|

Accelerator Pedal Adjustable

|

$121.13

|

1W1Z-2455-BB

|

2455

|

2001

|

2002

|

Brake Pedal Assembly (Motor and cable only

avaliable in accelerator pedal assembly)

|

$106.95

|

3W1Z-2455-BA

|

2455

|

2003

|

2003

|

Brake Pedal Assembly (Motor and cable only

avaliable in accelerator pedal assembly)

|

$106.95

|

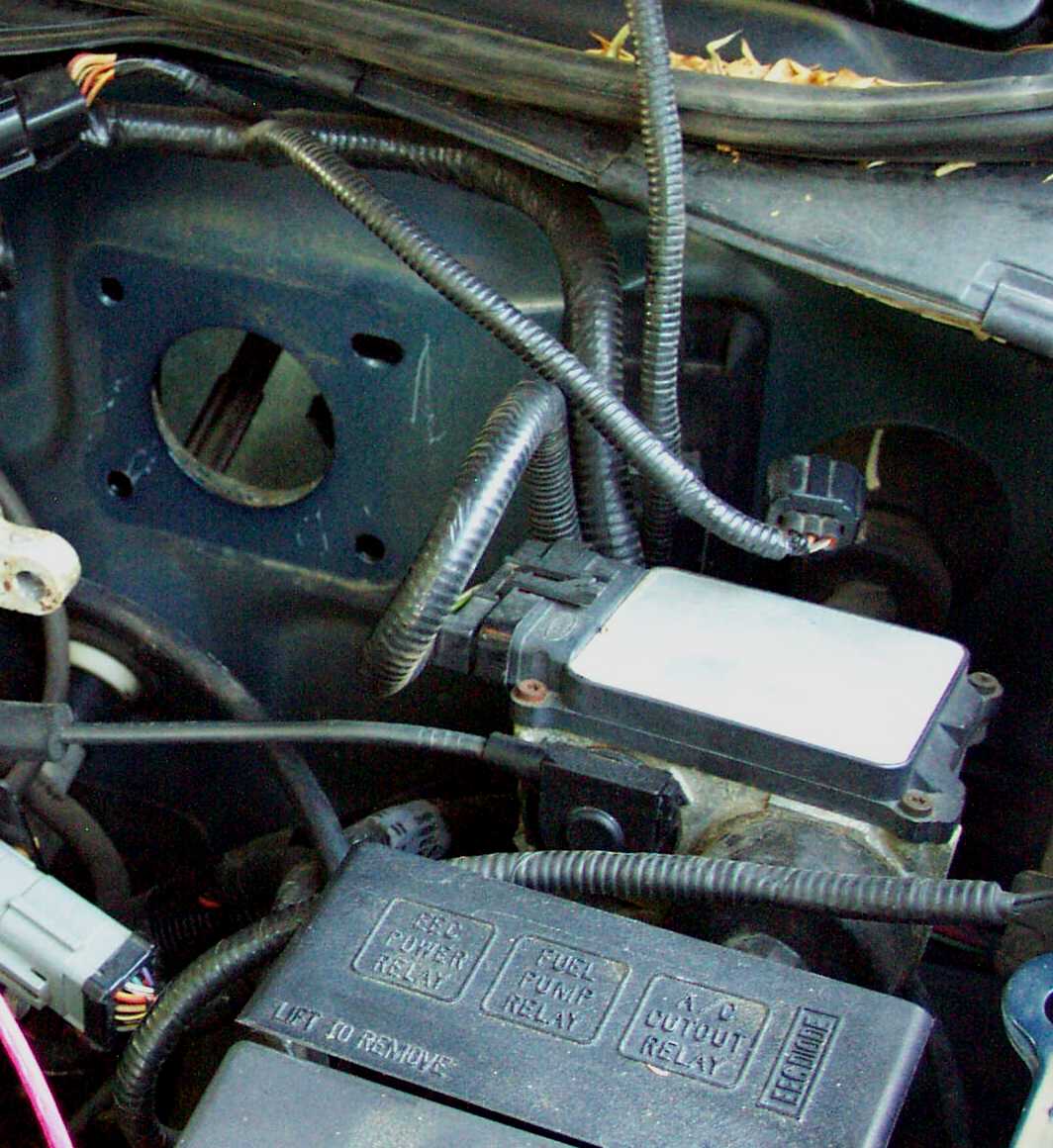

1W1Z-2005-AA

|

2005

|

2001

|

2002

|

Power Brake Booster Less Electronic Stability

Program (IVD) (use with #1W13-2B195-AC/BC or #1W73-2B195-CC)

|

$170.60

|

3W1Z-2005-AA

|

2005

|

2003

|

2003

|

Power Brake Booster Less Electronic Stability

Program (IVD)

|

$170.60

|