1992 and later crown victorias have a Drum-In-Hat (DIH) emergency brake

setup. Conventional hydraulic braking is accomplished by the brake

caliper clamping the brake rotor between two brake pads. To the surpise

of many crownvic owners, the emergency brake setup is actuated by

expanding a set of minature brake shoes against the inside of the brake

rotor hat.

Here is the driver's side rear of a 2005 crown victoria police

interceptor with the following components removed:

-rear wheel

-rear axle shaft

-wheel bearing

-brake rotor

-brake caliper

Here is the passenger's side of the car

The rear axle bearing on this side was trashed and the e-brake setup is

covered in differential oil as a result.

Here's one of the axle bearings and accompying seals after they have

been pulled out of the rear axle assembly

Here are the axle shafts

The axle shaft acts as an inner race for the bearing. When a bearing

fails, you'll often find a groove worn in the axle shaft where the

bearing rollers ride.

Also note that you'll sometimes need to swap the antilock brake tone

rings from your old axle shafts onto your new axle shafts. Some

aftermarket axle shafts don't come with tone rings at all. Worse yet,

some aftermarket axle shafts (i.e. dorman brand) do come with tone

rings, but they are the wrong size and don't fit properly with the

other rear axle parts.

Here's a closeup of the damage to the axle shaft.

That deep circular goove is not supposed to be there. In an extreme

case of wear like this, you'll want to thoroughly flush all the old oil

out of the differential because it will have metal shavings suspended

in it. If you don't clean out the metal shavings, you'll expierence

multiple repeat failures of the differential parts in the future. Some

people have also suggested replacing all the bearings in the

differential in a case like this because they are likely scored from

being exposed to metal for a while. When cleaning out the differential

housing, pay particular attention to the area where the axle tubes meet

the "pumpkin" that houses the carrier. There is a lip there where

debris collects that is often missed during oil cleaning procedures.

Here's the other end of the axle shafts where they would normally pass

into the differential carrier and have the c-clips installed. 2005

crownvics manufactured after 12/04/2004 have 31-spline axles instead of

the 28-spline axles that

you'll find in earlier vehicles.

Here are some other rear axle parts. Note the C-Clips in the lower

right portion of the picture.

In some of the earlier crownvics, you'll notice differential cover is

constructed of high grade stainless steel that doesn't rust like this.

Here's the other side of the differential. Also shown are the pinion

shaft and accompanying lock bolt. Note that the pinion lock bolt came

out clean in this case and didn't break in half.

Here are the rear brake rotors. Starting in the 2003 model year,

crownvic rear brake rotors received cooling vanes to help dissipate

heat. Prior to the 2003 model year, rear brake rotors were a solid

peice of iron without cooling fins.

Here is the back of the brake rotors showing the surface that the

e-brake shoes would normally lock against.

The pictures below were taken by DetroitP71

on

www.crownvic.net of his 2005 crown victoria police interceptor

during a rear axle shaft replacement project. As part of this project,

DetroitP71 decided to disassemble the e-brake system and clean the

parts up a little bit.

The circular hole on the on the right where the antilock brake wheel

speed sensor would normally be located. You'll need to remove this

sensor before you can push the axles inwards to remove the axle

c-clips. The shop manual makes rear anti-lock brake sensor

removal sound simple, first remove the retaining bolt, then slide the

antilock brake sensor out of the e-brake backing plate. Those of you in

the salt-belt will often find that you break the abs sensor during

removal, and will need to install a new wheel speed sensor. Ferritic

metal expands when it corrodes causing the wheel speed sensor to become

rust-jacked inside it's mounting hole.

Note: There are two different 2005 crown victorias shown here. The

pictures towards the top of this webpage are of an 05' P71 that lives

in the northeastern united states. The pictures towards the bottom of

this webpage are of an 05' P71 that lives in the midwestern united

states.

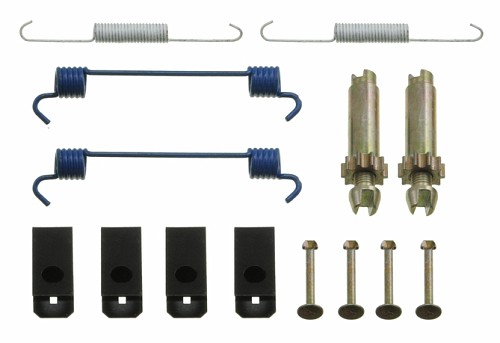

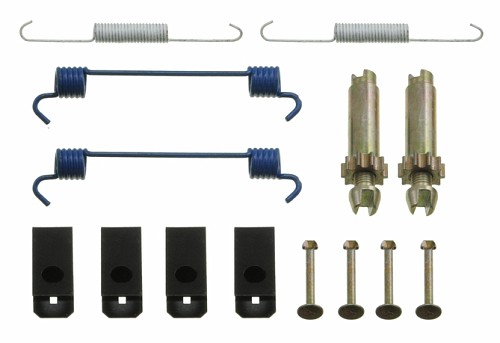

Replacement emergency brake shoes & hardware kits for 2003+

crownvics are avaliable

aftermarket. Aftermarket offerings include:

Autozone H7929 Hardware Kit

(Also sold as: Dorman HW7302 Hardware Kit)

Raybestos H7302 Hardware Kit

Raybestos 777PG Parking Brake Shoes

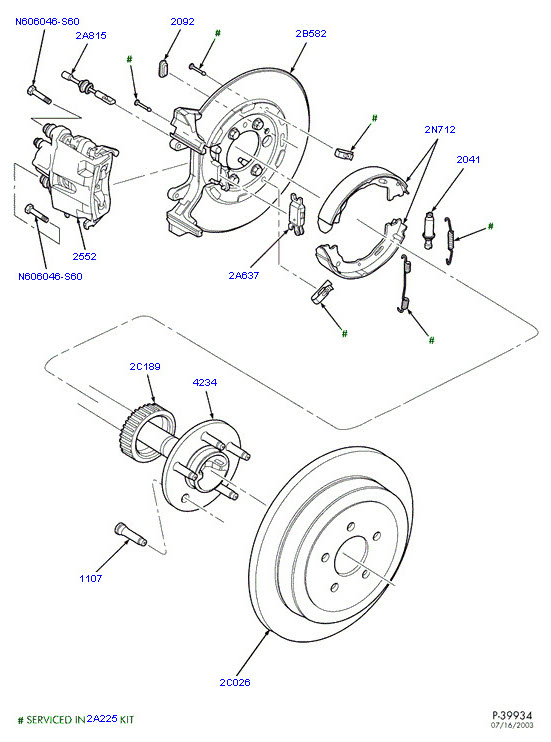

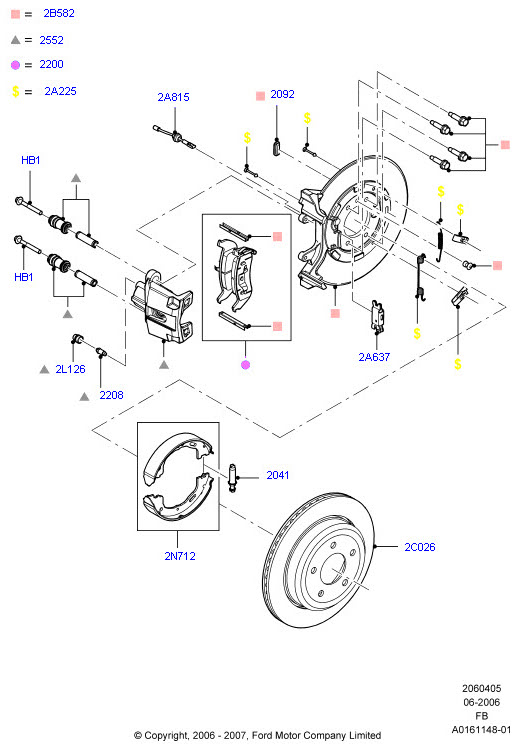

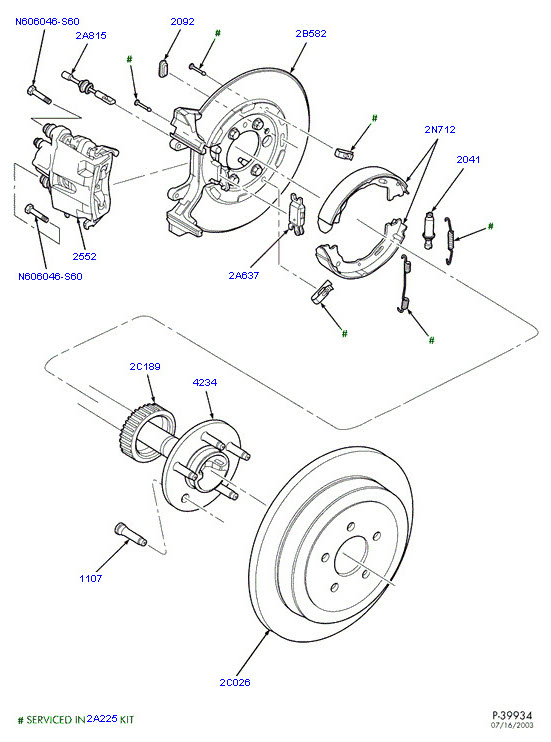

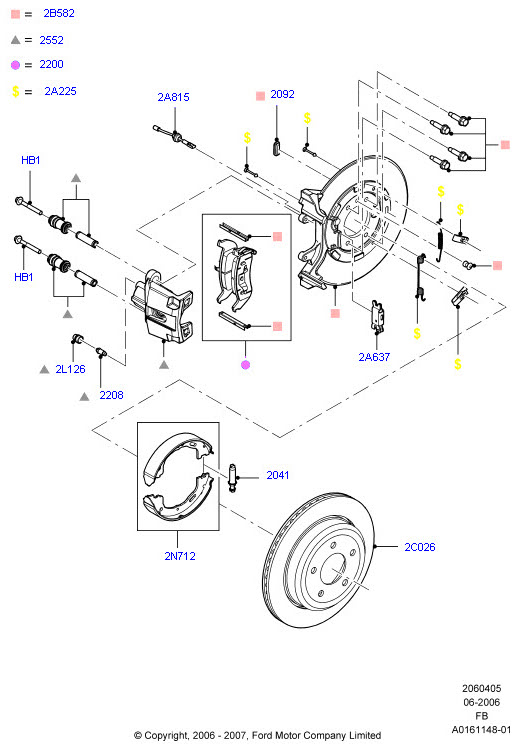

Ford service part diagrams

Ford Service Part Numbers

6W1Z-2B582-C Bracket - Brake Caliper, RH/LH (Brake Shoe Backing Plate)

(Replaces 3W1Z-2B582-AA) (2003-2010)

3W1Z-2A637-AA Lever - Parking Brake RH/LH (2003-2010)

F58Z-2092-A Plug - Inspection Opening (2003-2010)

6L2Z-2041-A Brake Adjuster, Screw Kit (Replaces 1L2Z-2041-AA)

(1996-2005)

6W1Z-2041-BA Screw - Adjusting, RH/LH (2006-2010)

3W1Z-2A225-AA Drum Brake Spring Kit (2003-2005)

6W1Z-2A225-AA Kit - Retracting Spring, RH/LH (2006-2010)

6W1Z-2N712-A Park Brake, Shoe & Lining Asy: [Kit - Services

RH & LH] (Replaces 3W1Z-2N712-AA & 5W1Z-2N712-A) (2003-2010)

9W1Z-2A815-A Parking Brake Intermediate Cable (Replaces 3W1Z-2A815-AA)

(2003-2010)

Parking Brake Shoe Linings

6W1Z-2N712-A (Replaces 3W1Z-2N712-AA & 5W1Z-2N712-A) (2003-2010)

Axle Service Part Numbers

3W1Z-4234-A 28-spline axle (manufactured to 12/04/2004) (replaces

3W1Z-4234-JA & 3W1Z-4234-KA & 3W1Z-4234-HA) (2003-2005)

6W1Z-4234-A 31-spline axle (manufactured from 12/04/2004) (replaces

5W1Z-4234-A) (2005-2010)

6W1Z-4234-B lincoln towncar limousine limited slip axle (replaces

3W1Z-4234-GA & 3W1Z-4234-LA & 4W1Z-4234-A) (2003-2010)